Five Different Types Of Performance Features Of PCB Designers

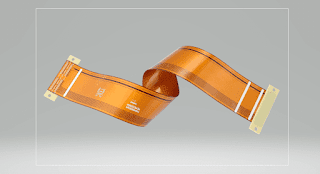

PCB stands for Printed circuit board and uses different types of materials as the components and substrates. The selection of material for the flexible PCB fabrication depends upon the choices of the materials. The manufacturers or the designers choose the circuits for facilitating the performance in specific situations. Designers also give importance to electrical performances for mechanical and thermal survivability. The regulatory government requirements are also necessary for compliance and selection. There are several types of performance features of PCB available. Performance Features Of PCB Designers The designers of PCB face several performance features while looking for material selection. Those are as follows. ● Dielectric constant : Dielectric constants are those that are key to the performance indicator. ● Mitigated loss factors : The mitigated loss factors are very crucial in the applications of high speed....