Exploring the World of Rigid-Flex PCBs: Fabrication, Assembly, and Advantages.

Rigid flex printed circuit boards (PCBs) are a unique type of PCB that combines the benefits of both rigid and flexible PCBs.

They are widely used in various industries, including aerospace, military, medical, and industrial automation.

We will discuss the process of rigid-flex PCB fabrication and the role of PCB assembly manufacturers in the production of these boards.

What is a Rigid-Flex PCB?

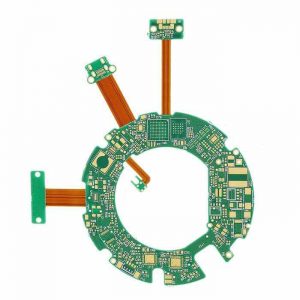

A rigid-flex PCB is a combination of a rigid PCB and a flexible PCB.

The rigid portion of the board provides structural support and houses components, while the flexible portion allows for movement and flexibility.

This unique design allows for compact and lightweight devices that can withstand harsh environments.

The Fabrication Process of Rigid-Flex PCBs

The fabrication process of rigid-flex PCBs is a multi-step process that involves several stages, including design, material selection, drilling, lamination, etching, and inspection.

The process starts with the creation of the PCB design, which is used as a blueprint for the manufacturing process.

The next step is the selection of materials, which typically include a combination of rigid and flexible materials.

The drilling process involves creating holes for components and connectors.

Lamination is the process of bonding the flexible and rigid layers together.

Etching is the process of removing unwanted copper from the board.

Inspection is the final step in the fabrication process, where the board is checked for any defects or errors.

The Role of PCB Assembly Manufacturers

PCB assembly manufacturers play a crucial role in the production of rigid-flex PCBs.

They are responsible for sourcing and purchasing the necessary components, as well as assembling them onto the board.

PCB assembly manufacturers also handle the testing and quality assurance of the finished product.

Some manufacturers also offer additional services such as design and engineering support, which can help customers with the development of their products.

Advantages of Using Rigid-Flex PCBs

One of the main advantages of using rigid-flex PCBs is their ability to provide structural support while allowing for flexibility.

They are also highly durable and can withstand harsh environments, making them ideal for use in industries such as aerospace and military.

They also allow for compact and lightweight devices, which can be crucial in certain applications.

Additionally, rigid-flex PCBs can reduce the number of components and connectors required, which can help to reduce costs.

Conclusion

Rigid-flex PCBs are a unique type of PCB that combines the benefits of both rigid and flexible PCBs. The fabrication process of these boards is a multi-step process that involves several stages, including design, material selection, drilling, lamination, etching, and inspection.

Source URL:: https://www.bizmakersamerica.org/blog/exploring-the-world-of-rigid-flex-pcbs-fabrication-assembly-and-advantages

Comments

Post a Comment